BrandTech™ VACUUBRAND™ ME 2 NT Diaphragm Vacuum Pump

VACUUBRAND™ ME 2 NT Diaphragm Vacuum Pumps are designed specifically for non-corrosive, non-evaporative applications. They are excellent for laboratory and process-plant applications including gas transfer, backing turbo pumps, and vacuum filtration. All wetted parts of these pumps are made of aluminum, FKM, and polyethylene. Aluminum-FKM pumps should not be used with organic solvents, corrosives, or other vapors inconsistent with the materials of construction.

A one-stage diaphragm pump is ideal for continuously pumping volatile gases and vapours without requiring a great deal of vacuum. Contrary to waterjet pumps, they do not consume water and thus do not produce any contaminated wastewater on a daily basis. Typical applications are vacuum ovens, filtrations and multi-port manifolds for medium-throughput, as well as pumping of gases and oil-free evacuation in general.

The pump combines a fast pumping speed with low ultimate vacuum down to 70 mbar. Fully assembled, ready to use, with instructions.

Features:

-

No Oil Changes

These vacuum pumps utilize diaphragm vacuum technology. The totally dry operation eliminates the misting, handling and disposal of contaminated waste associated with rotary vane pumps. No oil to change or monitor! -

Reduced Maintenance

Typical diaphragm lifetimes are well in excess of 15,000 hours of use before replacement - that's years in most applications, minimizing downtime and service costs. When it is finally time for service, their unique design eliminates tedious, trial-and-error stroke length recalibration. -

Improved Productivity

VACUUBRAND® pumps are engineered for performance, with flow rates as much as 40% higher at working vacuum level than competitive pumps with similar free air capacity ratings. Higher flow rates mean reduced process times and higher throughput. -

Reliability

All VACUUBRAND® pumps and systems must pass rigorous product testing before leaving the factory. It's your assurance of a reliable pump. -

Whisper Quiet Operation

- Aluminum and FKM wetted materials

- Low Maintenance - 15,000-hour service intervals typical

- Common Applications include gas transfer, filtration, and roughing for high vacuum systems

Specifications:

| Technical Data | ME2 NT |

| Number of Heads/Stages |

1/1 |

| Max. pumping speed at 50/60 Hz |

2.0/2.2m3/h |

| Max. pumping speed at 50/60 Hz |

1.2/1.3cfm |

| Ultimate Vacuum (abs.) |

70/52mbar/torr |

| Ambient Temperature Range (operation) |

10 - 40°C |

| Ambient Temperature Range (storage) |

-10 - 60°C |

| Max. Back Pressure (abs.) |

2bar |

| Inlet Connection |

Hose Nozzle DN 8-10mm |

| Outlet Connection |

Silencer/G1/4" |

| Rated Motor Power |

0.18kW |

| Rated Motor Speed at 50/60 Hz |

1500/1800min-1 |

| Protection Class |

IP 40 |

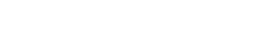

| Dimensions (L x W x H) |

243 x 211 x 198mm |

| Weight |

10.2kg |

| Noise Level at 50 Hz, typ. |

45dBA |

| NRTL Certification |

Canada and the USA |

| ATEX Conformity (only 230V) |

II 3/-G Ex h IIC T3 Gc X Internal Atm. only |

| Items Supplied |

Pump oil filled and completely mounted, ready for use, w/ manual |

Literature:

VaccuBrand ME 2 NT Diaphragm Pump Manual